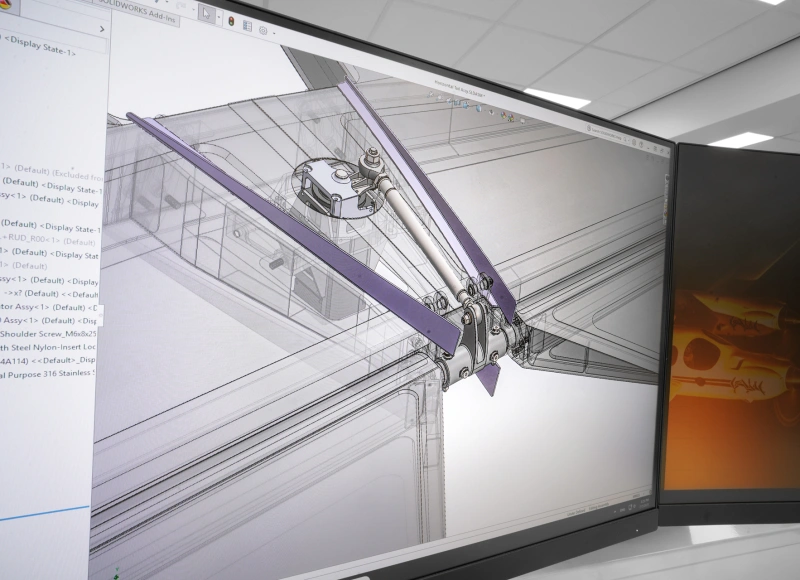

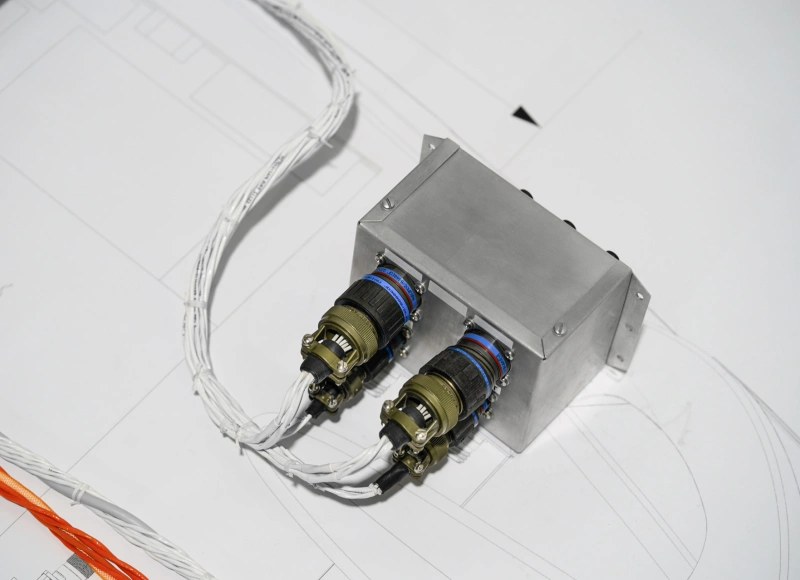

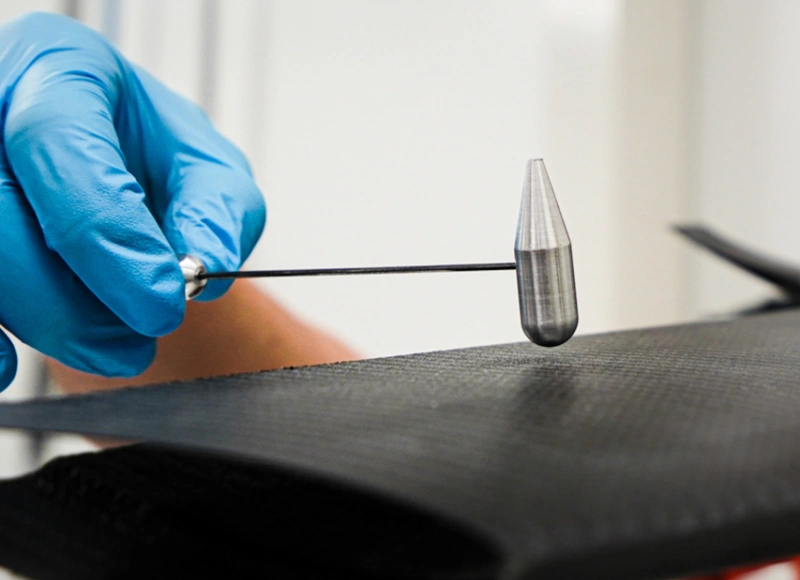

Through cooperation with all leading component manufacturers, we design and manufacture propulsion systems. We also manufacture high voltage power distribution including active and passive safety systems. Think of landing gear systems, parachute recovery systems, certified wiring harnesses using mill spec hook-up wire and connectors. For actuation systems we complete off the shelf components with in-house produced parts like hinges, axles, brackets, control rods and convolute gears, to provide a functional, low friction, close tolerance actuation system. Our avionics contain the integration of all commercially available autopilot systems including design and manufacturing of required peripherals. Through a partnership with Sovereign Autonomous Systems, we provide turnkey solutions with fully tuned, autonomous systems capable of autonomous landing and dynamic on-board flight path calculations.